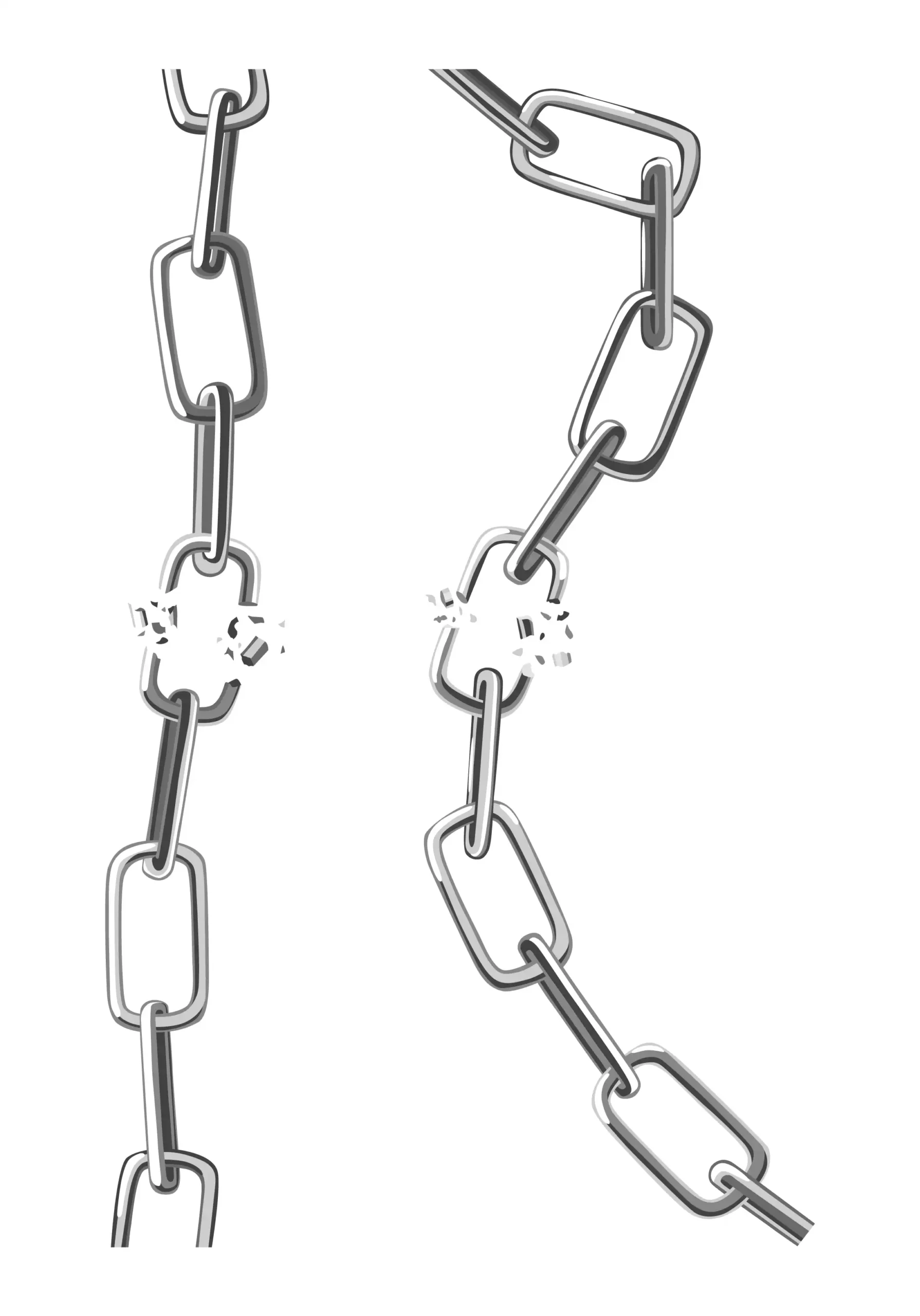

Understanding the concept of a ‘constraint’ is the first step towards understanding the Theory of Constraints (TOC). In this section, we explore this using the example of a chain.

“This weak link is the constraint.”

A constraint is a limitation that prevents a system from achieving its highest possible performance.

TOC reminds us: There are not hundreds of constraints. Just one, or a few.

The system cannot meet market demand.

Open the bottleneck using the 5 Focusing Steps.

The system can produce more than the market wants.

Increase demand.

“Just like a chain, a system’s performance is limited by its weakest element. In TOC, we focus not on all parts, but on the one link that matters most.”

Let’s schedule a 30-minute call to understand your unique challenges and explore how TOC can unlock growth for your business.